Advanced software tools of SES facilitating predictive maintenance of waste incineration plants

The good capacity utilisation of the German waste incineration plants means that almost all plants operate at maximum combustion capacity. A further increase in capacity can only be achieved by increasing operating hours, for example by avoiding unscheduled downtimes.

Thanks to developments in the field of control systems, it is now state-of-the-art to record and store sensor-based data in waste incineration plants in real time. Usually, these sensor-based data are archived in a central database and can be made available throughout the entire organization.

But it is difficult to assess the condition of the components under constantly changing external factors (weather, waste quality, load, pollutants, etc.). In order to meet these challenges, it is crucial to identify variations in the plant early on and in a reliable manner that indicate imminent damage or increased losses. With such information, the available resources can be used efficiently. Sources of loss in the process can be eliminated or reduced promptly and unplanned downtimes can be avoided by early maintenance measures.

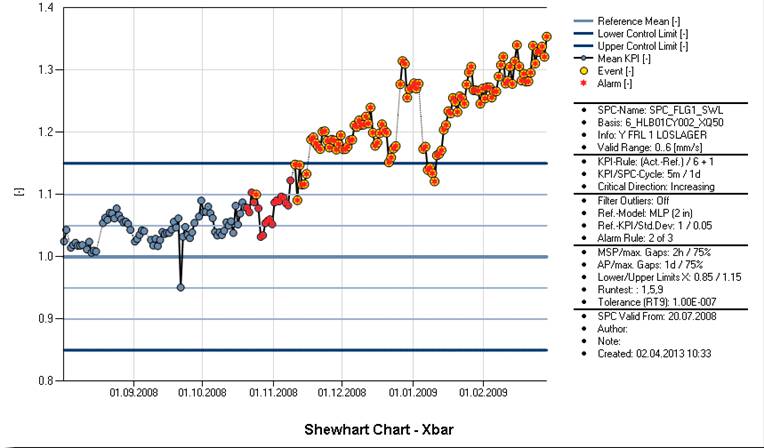

In the past, this early and trustworthy recognition of changes has often been achieved by experienced personnel. But on the one hand the task becomes more difficult with increasing variability in plant operation and on the other hand it has to be performed by fewer people. Our solution is the intelligent early warning system SR::SPC for the automatic process quality and condition monitoring of technical plants and their processes. SR::SPC is based on state-of-the-art data analysis. With predictive analytics as one of the most important big data trends at present, the current state of the plant or component is compared with reference states from history: Automatic process quality and condition monitoring allows the most important operating parameters to be continuously recorded in their mutual effects and history. The use of SES software solutions helps to extend operational lifetime and reduce unplanned downtimes.